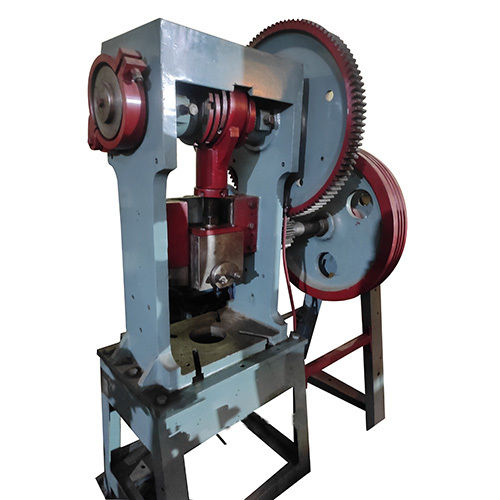

Pillar Type Power Press Machine

Product Details:

- Size Different Sizes Available

- Material Stainless Steel

- Application Industrial

- Click to View more

Pillar Type Power Press Machine Price And Quantity

- 10 Unit

Pillar Type Power Press Machine Product Specifications

- Industrial

- Stainless Steel

- Different Sizes Available

Pillar Type Power Press Machine Trade Information

- Cash Advance (CA)

- 1000 Unit Per Month

- 10 Days

- All India

Product Description

A mechanical press called a pillar type power press machine, sometimes referred to as a pillar press or pillar drill press, is frequently used in the metalworking, woodworking, and other industries. Its unusual pillar- or column-like structure, which lends the machine strength and stability, gave rise to its name. The pillar press is generally utilised for various materials' drilling, reaming, countersinking, and tapping activities.

Here are some essential characteristics and parts that are frequently present in pillar type power press machines:

1. The pillar, also known as a column, is a vertical structural component that gives the machine support and stability. It is typically constructed of steel or cast iron and is built to withstand the forces produced during drilling operations.

2. Base: The base is a substantial, flat platform that gives the machine a secure foundation. It aids in ensuring the machine's steadiness while in use and lessens vibrations.

3. Worktable: The worktable is a flat surface that is fastened to the machine's base or pillar. During drilling operations, it offers a platform for holding and moving the workpiece. Typically, the worktable can be tilted and raised to accommodate a variety of workpiece sizes and angles.

4. Drill Head: The drill head is the machine's upper section, where the motor, spindle, and other parts are located. It is attached to the pillar's top and can be moved vertically along the pillar to accommodate various drilling depths.

5. The revolving part known as a spindle holds the cutting instrument, such as a drill bit, and provides the rotational motion required for drilling. The spindle is powered by a motor, and its speed can frequently be changed to meet various drilling needs.

6. Feed Mechanism: The drill head's vertical movement may be managed by a feed mechanism in the pillar press. This device, which can be used manually or with power aid, enables for exact drilling depth control.

7. Control system: A control system that enables the modification of drilling speed, feed rate, and other parameters may be present in some pillar type power press machines. This control system offers improved accuracy and simplicity of use.

8. Pillar presses frequently have safety mechanisms to safeguard the operator while in use. Safety guards, emergency stops, and safety switches are a few examples of these that help avoid accidents and injuries.

Large floor-standing machines as well as smaller benchtop variants are available in pillar type power press machines. The precise needs of the application will determine the size of the drill capacity, motor power, and other specifications.

To avoid mishaps and achieve the greatest drilling outcomes when using a pillar type power press machine, it's crucial to adhere to the right safety precautions, put on the required personal protection equipment, and properly setup and clamp the workpiece.

FAQ

1. What types of materials are compatible with the Pillar Type Power Press Machine?

Ans - Depending on the machine's parameters, the Pillar Type Power Press Machine can be used with sheet metal, plastic, and wood.

2. What is the Pillar Type Power Press Machine's power consumption?

Ans - The size and kind of the machine determine how much power the Pillar kind Power Press Machine uses.

3. What characteristics does the pillar-type power press machine possess?

Ans - The Pillar Type Power Press Machine can make tiny or large components, has adjustable speed and stroke control, and produces product quickly and effectively.

4. What safeguards are present in the Pillar Type Power Press Machine?

Ans - The emergency stop buttons, hand guards, and eye shields are among the security elements included in the Pillar Type Power Press Machine's design.

5. Is maintenance necessary for the Pillar Type Power Press Machine?

Ans - Yes, routine maintenance is necessary to keep the Pillar Type Power Press Machine performing at its best.

Other Products in 'Power Press Machine' category

|

Ezzi Iron Works

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry